GE GF868-2-2EX-21A14-0-0-S Industrial Drive

High-Performance Variable Frequency Drive for Industrial Applications

Overview

The GE GF868-2-2EX-21A14-0-0-S is a high-performance variable frequency drive designed for demanding industrial applications. As part of GE's advanced drive portfolio, this robust drive provides precise motor control, energy efficiency, and reliable performance in a compact, rugged package suitable for harsh industrial environments.

Engineered for seamless integration with various industrial systems, the GF868-2-2EX-21A14-0-0-S offers advanced control algorithms, flexible configuration options, and comprehensive diagnostic capabilities. Its modular design ensures easy installation, maintenance, and system expansion, making it ideal for applications requiring precise speed control and energy optimization.

Specifications

Power Specifications

- Input Voltage: 400-480 VAC, 3-phase

- Voltage Range: 380-528 VAC

- Output Power: 2.2 kW (3 HP)

- Output Current: 5.8 A continuous, 17.4 A peak

- Frequency Range: 0.1-500 Hz

Control Specifications

- Control Modes: V/f, Vector, Sensorless Vector

- Motor Types: Induction, Permanent Magnet

- Speed Regulation: ±0.5% (V/f), ±0.01% (Vector)

- Carrier Frequency: 2-16 kHz (adjustable)

- Control Resolution: 0.01 Hz

Environmental Specifications

- Operating Temperature: -10°C to 50°C

- Storage Temperature: -40°C to 70°C

- Humidity: 5% to 95% non-condensing

- Altitude: Up to 1000 meters (derate above)

- IP Rating: IP21 (NEMA 1) standard, higher options available

Physical Specifications

- Dimensions: 180 x 140 x 250 mm

- Weight: 4.5 kg (approx.)

- Mounting: Wall mount, cabinet mount

- Cooling: Fan-cooled with thermal management

- Enclosure: Powder-coated steel

Features

Advanced Control Algorithms

Incorporates advanced vector control algorithms for precise motor control and energy optimization. Supports multiple control modes including V/f, sensorless vector, and closed-loop vector control for various application requirements.

Energy Efficiency

Built-in energy optimization features including automatic flux optimization, sleep/wake functions, and energy monitoring. Reduces energy consumption by up to 30% compared to direct-on-line starting in many applications.

Comprehensive Protection

Advanced protection features including overcurrent, overvoltage, undervoltage, overtemperature, short circuit, ground fault, and phase loss protection. Ensures reliable operation and protects both the drive and connected equipment.

Flexible Connectivity

Multiple communication options including Modbus RTU, Profibus DP, DeviceNet, EtherNet/IP, and Profinet. Facilitates seamless integration with industrial control systems and building automation networks.

Advanced Diagnostics

Comprehensive diagnostic capabilities including real-time parameter monitoring, fault logging, oscilloscope functionality, and event history. Enables quick troubleshooting and minimizes downtime in critical applications.

Modular Design

Modular design with optional I/O expansion cards, communication modules, and braking units. Allows for easy customization and system expansion to meet changing application requirements.

Applications

Pumping Systems

Ideal for centrifugal pumps, process pumps, and HVAC pumping systems. Provides precise flow control, energy savings, and reduced mechanical stress on pump systems through soft starting and variable speed operation.

HVAC Systems

Perfect for fans, blowers, and air handling units in commercial and industrial HVAC applications. Enables precise temperature and humidity control while significantly reducing energy consumption.

Conveyor Systems

Well-suited for belt conveyors, roller conveyors, and material handling systems. Provides smooth acceleration/deceleration, precise speed control, and torque regulation for efficient material transport.

Industrial Fans & Blowers

Excellent for industrial fans, blowers, and exhaust systems. Enables variable air flow control, energy optimization, and reduced noise levels compared to fixed-speed operation.

Machine Tools

Suitable for various machine tool applications including lathes, milling machines, and grinders. Provides precise speed control and torque regulation for improved加工精度和效率.

Water & Wastewater Treatment

Designed for water treatment pumps, aeration systems, and mixing equipment. Enables efficient process control, energy savings, and reliable operation in demanding water and wastewater applications.

Technical Details

Control Features

- Acceleration/Deceleration: 0.1-3600 seconds

- S-curve: 0-100% adjustable

- Multi-step Speed: Up to 16 preset speeds

- Process PID: Built-in PID controller

I/O Configuration

- Digital Inputs: 6 configurable inputs

- Digital Outputs: 2 relay outputs, 2 transistor outputs

- Analog Inputs: 2 x 0-10V / 4-20mA

- Analog Outputs: 1 x 0-10V / 4-20mA

Communication Protocols

- Standard: Modbus RTU (RS-485)

- Optional: Profibus DP, DeviceNet

- Industrial Ethernet: EtherNet/IP, Profinet

- BACnet: BACnet/IP, BACnet MS/TP

Protection Features

- Overcurrent Protection: Instantaneous and thermal

- Voltage Protection: Overvoltage, undervoltage

- Thermal Protection: Drive and motor thermal protection

- Other: Short circuit, ground fault, phase loss

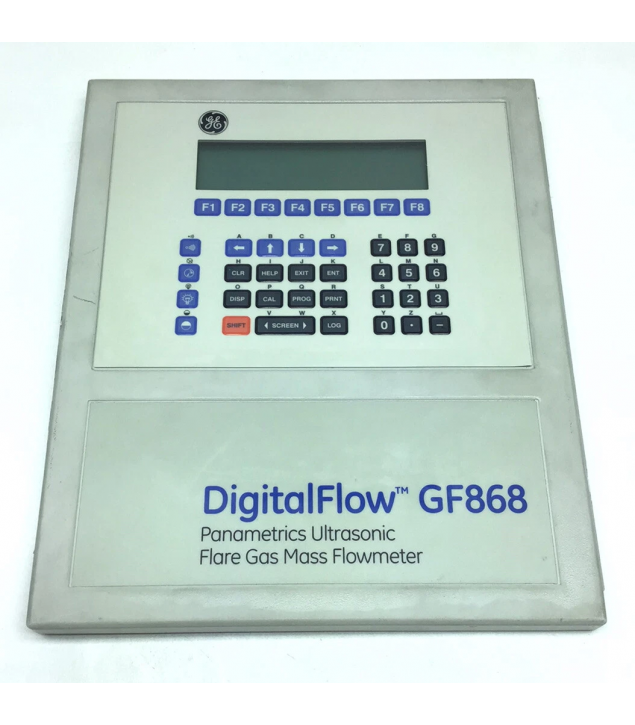

Display & Programming

- Display: Backlit LCD with navigation keypad

- Programming: Keypad, PC software, remote keypad

- Parameter Storage: Non-volatile memory

- Language Support: Multiple languages

Compliance & Certifications

- Safety: CE, UL, cUL, TÜV

- EMC: EN 61800-3, EN 55011

- Harmonics: EN 61000-3-2, IEEE 519

- Environmental: RoHS, REACH compliant

Additional Information

Commissioning & Maintenance

The GE GF868-2-2EX-21A14-0-0-S drive features intuitive programming software and a user-friendly keypad for easy setup and configuration. The drive includes auto-tuning capabilities that optimize performance based on the connected motor and load characteristics. Regular maintenance includes periodic inspection of cooling fans, cleaning of heat sinks, verification of electrical connections, and firmware updates to ensure optimal performance and compatibility with the latest control systems.

GE provides comprehensive technical support through a global network of service centers and authorized distributors. Factory training programs are available for system integrators and maintenance personnel. The drive comes with a 1-year manufacturer's warranty, and extended warranty options are available for critical applications. Software updates, technical documentation, and spare parts are readily available through GE's extensive service network.

General Electric Company

Industrial Automation Solutions

Document Number: GF868-2-2EX-21A14-0-0-S-DOC

Last Updated: 2025